Vertical Storage Tank - Hot Water Boilers

Assos Floor Standing Boilers, Hot Water Boilers, Storage Tank Manufacturers

Cost-effective, durable boilers ideal for both home and professional use, made from quality, eco-friendly materials.

On this page, you will find information, specifications, and technical data about the Assos Vertical Boilers, provided by Solarnet S.A., a Boiler Storage Tanks Manufacturer.

On this page, you will find information, specifications, and technical data about the Assos Vertical Boilers, provided by Solarnet S.A., a Boiler Storage Tanks Manufacturer.

“Assos Boilers” are manufactured in various types and can also be used as hot water storage tanks. They comply with DIN 4753 and EN 12897 specifications, are tested according to the international hygiene regulations, and have a capacity ranging from 150 to 1000 liters.

Assos hot water boilers are ideal for home use as well as for hotels, offices, mansions, etc, are provided with single, double, triple power sources with buffers and are available in 5 different colors. Their insulation of high-density cast polyurethane is eco-friendly and ensures hot water for longer. Furthermore, Assos hot water boilers are the fastest on the market due to their large heat exchanger, making them also cost-effective.

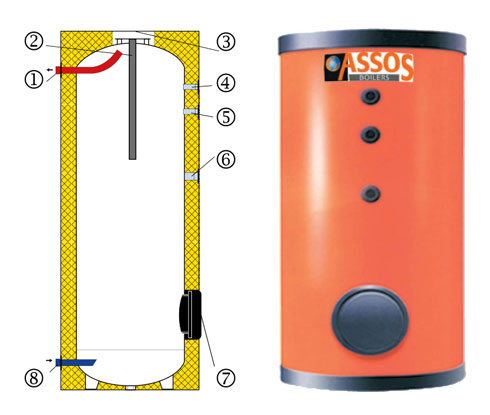

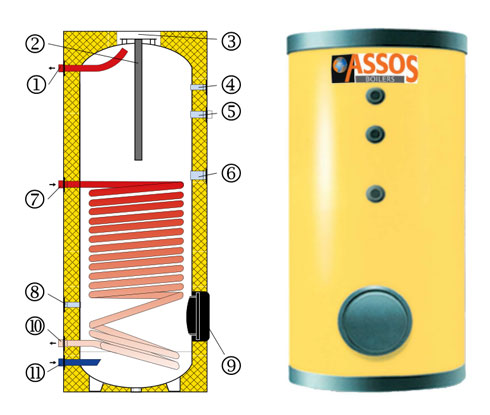

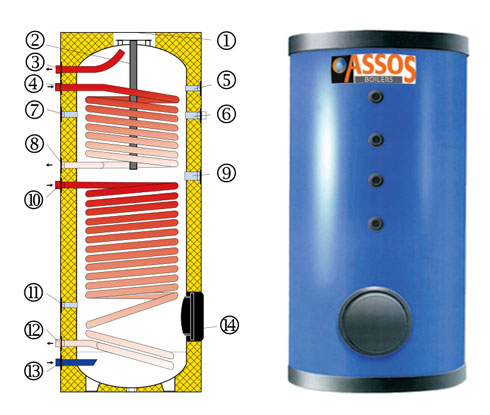

The types of vertical hot water boilers and storage tanks are the following:

- Type BL0, without coils (150, 200, 300, 420, 500, 800 & 1000 litres)

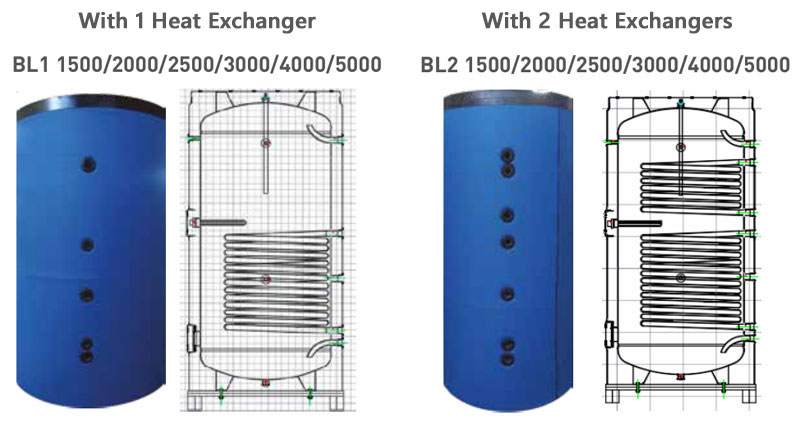

- Type BL1, with one coil heat exchanger (150, 200, 300, 420, 500, 800, 1000, 1500, 2000, 2500, 3000, 4000, and 5000 litres)

- Type BL2, with two coil heat exchangers (150, 200, 300, 420, 500, 800, 1000, 1500, 2000, 2500, 3000, 4000, and 5000 litres)

- BUFFER-0, BUFFER-1, MEGA TANK INOX (buffer tank) (150, 200, 300, 420, 500, 800, and 1.000 litres)

- Type FRW1, (Fresh Water) 150L - 200L - 300L Hot water tank for heat pump - solar water heaters

General Characteristics of Assos Boilers

Water Storage Tanks:

- Material: Steel plate USD37.2 quality

- Welding: Robotically welded in an inert gas environment

- Cleaning: 6-point metal blasting

- Internal protection: Glass enamel baked at 850° C

- Function Pmax: 6 bar

- Testing Pmax: 15 bar for 5 minutes

- Function Tmax: +95° C

Insulation:

- Material: Polyurethane CFC & FCKW Free

- Density: 40 kg/m3

- Thickness: 65 mm

(For storage tanks 800, 1000, insulation is made from flexible polyurethane 70 mm and is detachable for easier passage during installation)

Outer Cover Material: PVC in various colors

Heat Exchanger Type: Coil heat exchanger made of heavy-duty steel tube 33mm (tubo).

Heating Element (upon request): 2 kW to 4 kW (220-240V, one-phase) with thermostat or 6 kW, 9 kW, or 12 kW (three-phase, 380V) without thermostat.

Thermostat

- Regulation: between 30° C - 80°C

- Contacts: bakelite – silver

- Protection cap from nylon 6 (flame retardant).

- 230 V /20 A

![]() Certificate for drinking water

Certificate for drinking water